Compressed air can be contaminated by dirt, water and oil, which can damage the downstream appliances. SUNWIN, thanks to its 17 years experience in this sector offers a wide range of in-line filters for removing these contamination and protecting the equipment served by compressed air, according to the ISO 8573-1 standards.

Replacement Cartridges

Specifications of filter elements

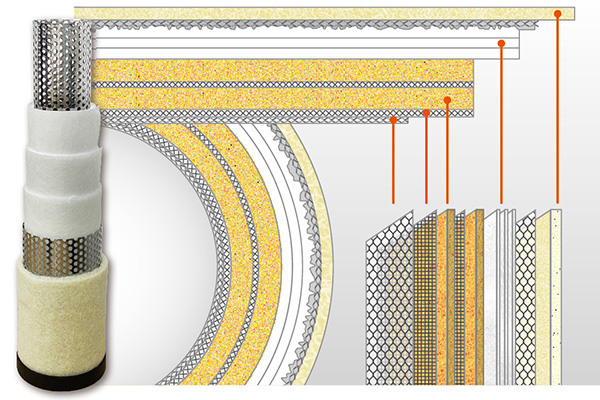

Separator filter (C)

For bulk liquid removal plus a 3 micron coalescer (5ppm w/w maximum remaining oil content).

Two-stage filtration

◆ First stage: two stainless steel orifice tubes provide

10 micron mechanical separation.

◆ Second stage: in-depth fiber media captures solid and liquid particles to 3 micron.

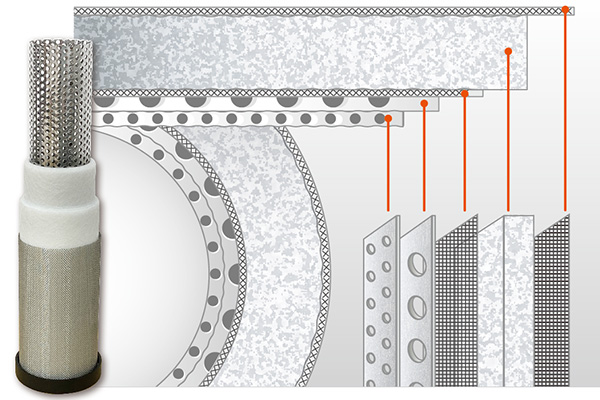

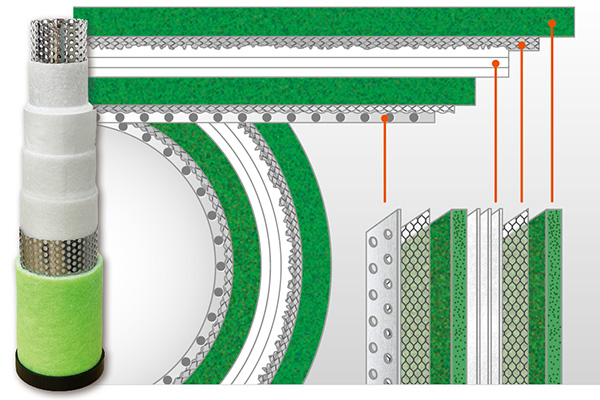

Air line filter (T)

For removal of liquid water and oil; removes solid particles to 1 micron (1.0 ppm w/w maximum remaining oil content) Corrosion resistant inner and outer cores. Two-stage filtration

◆ First stage: captures larger particles with alternate layers of fiber media and media screen.

◆ Second stage: coalesces aerosols and captures solid particles with multiple layers of epoxy bonded, blended fiber media.

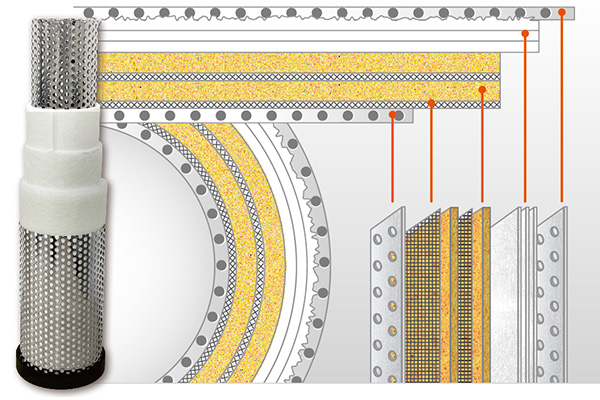

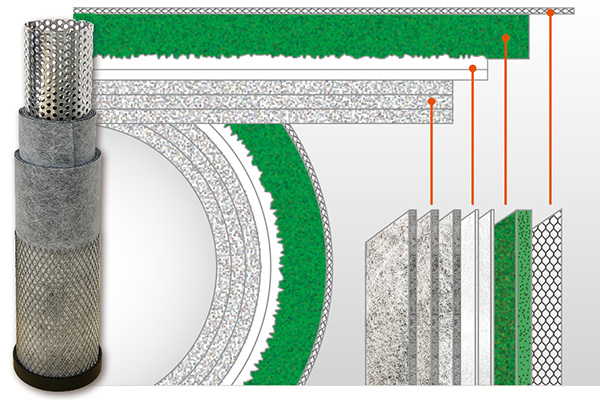

High efficiency oil removal filter (A)

For coalescing fine water and oil aerosols; removes solid particles to 0.01 micron (0.01 ppm w/w maximum remaining oil content).

Corrosion resistant inner and outer cores. Two stage filtration

◆ First stage: multiple layers of bonded, blended fiber media for fine coalescence.

◆ Second stage: multiple layers of bonded, blended fiber media for fine coalescence.

Outer coated, closed cell foam sleeve.

Ultra high efficiency oil removal filter (AA)

For coalescing ultra-fine oil aerosols; removes solid particles to 0.01micron (0.001 ppm w/w maximum remaining oil content). Corrosion resistant inner and outer cores. Two stage filtration

◆ First stage: coated, closed cell foam sleeve acts as pre-filter and flow disperser.

◆ Second stage: multiple layers of matrix blended fiber media for ultra-fine coalescence. Outer coated, closed cell foam sleeve.

Oil vapor removal filter (H)

For removal of oil and hydrocarbon vapors normally absorbable by activated carbon; removes solid particles to 0.01 micron(0.003 ppm w/w maximum remaining oil content). Corrosion resistant inner and outer cores. Two stage filtration

◆ First stage: a stabilized bed of finely divided carbon particles removes the majority of the oil vapor.

◆ Second stage: multiple layers of fiber media with bonded micro fine carbon particles removes the remaining oil vapor. Multiple layers of fine media prevent particle migration Outer coated, closed cell foam sleeve prevents fiber migration Designed for 1000 hour life at rated conditions.

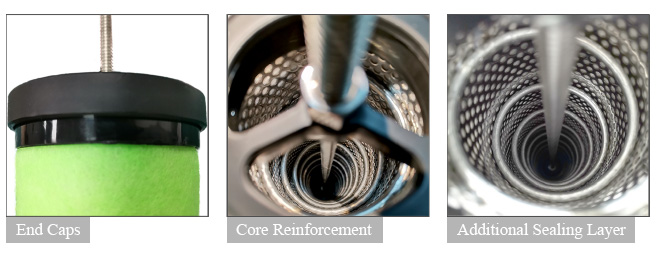

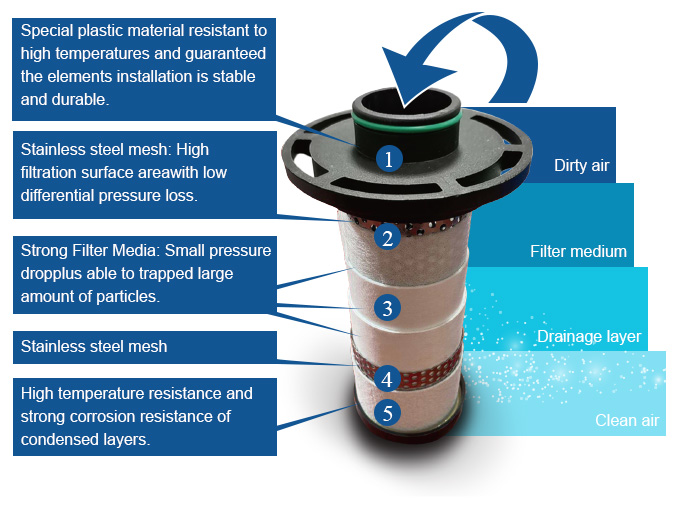

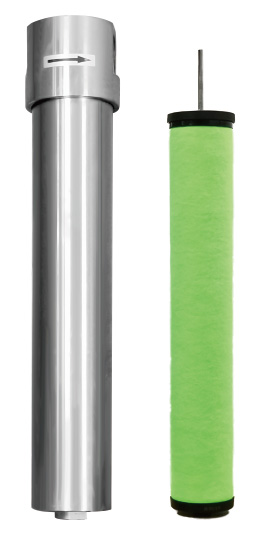

High Pressure Air Filter Elements

◆ The filter housing produced with the numerical control precision machining and the high temperature pressure test experiment.

◆ The materials include stainless steel, carbon steel respectively 4.0Mpa 5.0Mpa pressure levels.

◆ This air filter is suitable for special gas, high efficiency, corrosion resistance and high temperature resistance as corrosion-resistant surface treatment was performed both.

◆ The filter element with advanced materials and stable stainless steel bones, to achieve efficient precision filtration effect.