Removal of condensate from compressed air system is a critical maintenance requirement. Failure to carry out regular draining results in serious disruption to production schedules, deterioration in product quality, and damage to sensitive pneumatic equipment. Eliminates the risk of human error and possible costly aftermath by providing regular system drainage.

A drain valve is simply a device that allows excess moisture to be drained from the compressed air system. It is used at low points in the system where water collects. The valve mechanism can be opened to allow water to drain out via gravity and closed to prevent air from escaping once the water has drained. Drain valves may be found on compressors, air dryers, air receiver tanks, inline filters, and at low points in the compressed air piping. They should be used anywhere moisture may collect in the compressed air system. Sunwin’s most popular drains includes float drains, electronic drains and zero air loss drains.

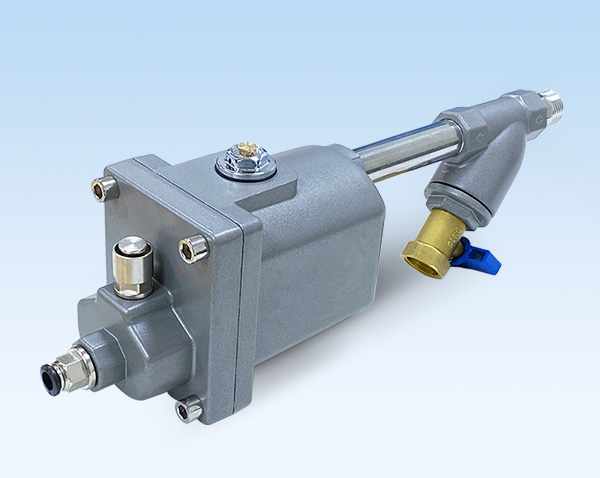

Zero Air Loss Drainer

Removal of condensate from compressed air system is a critical maintenance requirement. Failure to carry out regular draining results in serious disruption to production schedules, deterioration in product quality, and damage to sensitive pneumatic equipment. Eliminates the risk of human error and possible costly aftermath by providing regular system drainage. Compared with traditional drains, zero air loss drains save compressed air energy and is a more cost-effective choice for you, Sunwin’s most popular zero air loss drains is WK-58, which is float type ball zero air loss drain, no electricity required, usually installed under the air tank with large capacity of 680L/H.

◆ Automatic cleaning function.

◆ Remove condensate without wasting compressed air.

◆ Large-diameter valve nozzle, easy to discharge oil, rust and pipe scale.

◆ Long-life all-stainless steel valve nozzle design, pressure-resistant design.

◆ Large-volume: double-layer strainer.

Technical specification of Zero Air Loss Drainer

Model

Inlet Connection

Outlet Connection

Working Pressure

Max Working Temperature

Capacity

WK-10 / WK-58

Rc1/2″, Rc1/2

Rc1/8″, Rc3/8″

16bar

100℃

280L/H&680L/H

Float Type Ball Drainer

It is often used to automatically remove accumulated water at the bottom of pipelines, refrigerated air dryers, oil-water separators, air storage tanks and the bottom of various air filters. It can be installed in places where it is inconvenient to discharge sewage manually, such as high places, low places, and narrow places; especially in places with large gas consumption and frequent water discharge, it can prevent the compressed air from being forgotten due to artificial drainage. Water is re-polluted.

◆No Electricity Required

◆Working Pressure:16Bar

◆Working Temperature: 100℃

◆Die Casting Aluminum Shell, Powder Coated

◆Stainless Steel Float Ball & Hardware

◆1/2″ NPT Female Inlet and Outlet Connection

◆Equipped With “Anti Air Lock” Vent Tube Discharges Condensate “Not Air”

Condensate from the filter will flow beside the vent tube and accumulate in the drain reservoir. As the condensate accumulates the liquid will cause the float to rise and force air out through the tube and discharge valve expelling the liquid. After the liquid is expelled the float will return to the low position and the discharge valve will closes until the cycle is repeated. Each float type ball drainer is equipped with an “Anti Air Lock” vent tube which prevents loss of compressed air.

Technical specification of Float Type Ball Drainer

Model

Inlet Connection

Outlet Connection

Max Working Pressure

Max Working Temperature

Capacity

SWD20B/SWD30B/SWD40B

Rc1/2″

Rc1/2″

16bar

100℃

400L/H&600L/H&8L/H

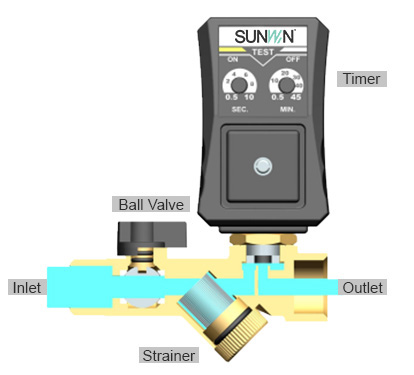

Electronic Drainer

The SUNWIN electronic auto drainer controlled condensate drainer combines an adjustable electronic timer controlled drain, a ball valve and a mesh strainer into one compact easy to install package. Suitable for any flow range and pressure up to 16bar (230 PSI), the drainer is perfect for virtually any compressed air application, especially those with solid particulate contaminants.

◆Available in High Pressure (up to 40Bar)

◆Easily adjustable electronic timer

◆Direct acting solenoid valve

◆Large discharge orifice

◆Cost effective

◆Test switch, LED on/off indication

◆ON Time: 0.5 – 10 Seconds

◆OFF Time: 0.5 – 45 Minutes

◆Brass body with stainless steel internals

With a test button, LED on/off indication and a full serviceable direct acting valve, the drainer offers affordable, reliable condensate management without the need to install additional valves and strainers. Use it on any compressor, receiver, filter or refrigerated dryer. The saves installation time and protects against large particles found in condensate, thanks to the integrated ball valve and strainer. The unit can be shut off from the compressed air system, enabling easy and safe work to be carried out.

Technical specification of Electronic Drainer

Model

Inlet Connection

Outlet Connection

Interval Time

Discharge Time

Power Supply

Max Working Temperature

Max Working Pressure

SRPT-16B/SRPT-40B

Rc1/2″

Rc1/2″

0.5 – 45 minutes

0.5 – 10 seconds

220V± 10% 50/60Hz

50℃

16bar/40bar

Applications

Bespoke: Professional and personalised solutions

17 years of OEM experience, exports to more than 30 countries worldwide, 3,000 m2 of production facilities, a professional technical team, professional advice at all times, SUNWIN – the compressed air aftertreatment specialist is at your side!

Welcome to our custom refrigeration dryer page! If you’re looking for a reliable and efficient solution for removing moisture from compressed air in your specific application, you’ve come to the right place. Our custom refrigeration dryers are designed to meet your unique requirements and deliver exceptional performance in even the most demanding environments.

At SUNWIN, we have extensive experience in designing and manufacturing refrigeration dryers for a wide range of industries, including [list of industries].

Our team of experts will work closely with you to understand your specific needs and provide you with a customized solution that meets your technical and budgetary requirements.

Whether you need a refrigeration dryer for a small workshop or a large industrial plant, we can help you find the right solution. Our custom refrigeration dryers come in a variety of sizes and configurations, and can be tailored to meet your specific application needs. Plus, our advanced technology and high-quality components ensure reliable and energy-efficient operation, saving you money and reducing your environmental impact.

Keep reading to learn more about the benefits of our custom refrigeration dryers and how we can help you improve the performance of your compressed air system. If you have any questions or would like to request a quote, please don’t hesitate to contact us. Our team is ready to assist you in finding the right solution for your unique needs.

Customization Options

At Sunwins, we understand that every customer has unique needs and requirements when it comes to compressed air drying solutions. That’s why we offer a wide range of customization options to ensure that our refrigeration dryers meet your specific needs.

Color and Appearance

We offer OEM services to cater to various clients, including customization of the overall color scheme to align with their brand image. OEM services to cater to various clients

Control Options

We offer a range of control options for our refrigeration dryers, including basic manual controls, advanced digital controls, and programmable logic controllers (PLCs). This allows you to choose the level of control that best suits your needs, whether you need simple on/off functionality or more advanced automation and monitoring capabilities.

Installation and Integration

We offer customized product design and integration services to meet unique customer needs. Whether it’s large-flow, ultra-low pressure refrigerated dryers or other special requirements, our team provides complete design solutions. We work closely with customers to ensure smooth integration and optimal performance. From system layout to control systems, we deliver tailored solutions for specific requirements.

Additional Features

We understand that different regions and environments may have unique requirements. That’s why we offer a range of additional optional features to cater to specific needs. These include different refrigerants, voltage options, and pressure levels, among others. Our goal is to provide flexibility and customization, allowing customers to tailor the product to their specific operating conditions.

Whatever your needs, our team of experts is here to work with you to create a customized refrigeration dryer that meets your exact specifications. Contact us today to learn more about our customization options and how we can help meet your compressed air drying needs.

Features and Benefits

- Free Consultation and Design: We provide free consultation and design services to our customers. Our team of experts is available to understand your requirements and offer tailored solutions to meet your needs. Whether you need assistance with product selection or system design, our knowledgeable professionals are here to guide you.

- Proven Materials and Components: We use materials and components that have undergone years of market testing and validation. This ensures that our products are built with high-quality parts, delivering reliable performance and longevity.

- Industry Experience: With extensive industry experience, we are well-equipped to ensure the quality and effectiveness of our products. We understand the challenges faced by different industries and have the expertise to address them during the product procurement phase.

- Cost-Effective Solutions: Our products are designed with cost-effectiveness in mind. We prioritize energy efficiency and low maintenance requirements, helping you save on operational costs in the long run.